Frequently Asked Questions

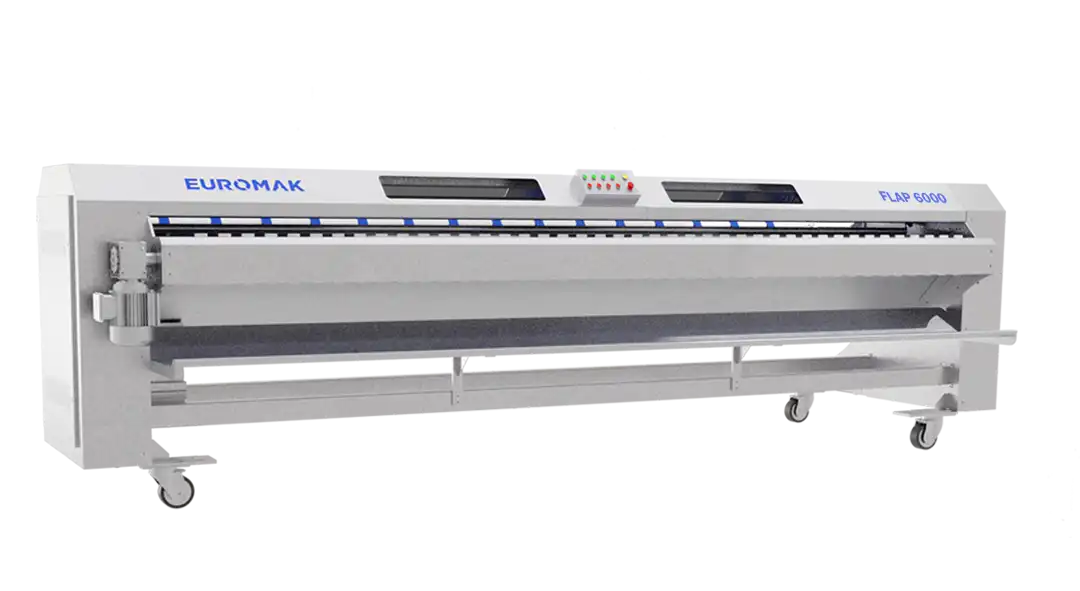

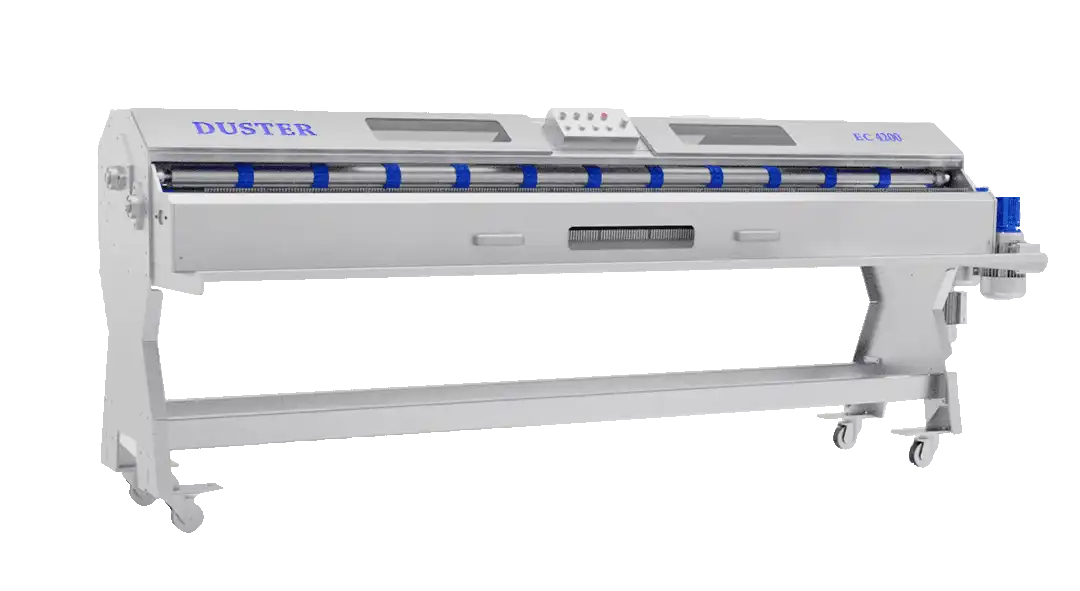

How does a carpet dust remover machine work?

The working principle of industrial carpet dust remover machines is straightforward. These machines apply equal amounts of impact to all parts of the carpet, which causes hair, fur,

dust, and other foreign particles trapped in the carpet fibers to rise to the surface. Subsequently, a robust vacuum system is employed to effectively remove these particles from the carpet surface,

thus completing the initial step of the cleaning process.

How can efficient and effective cleaning be achieved with carpet dust remover machines?

Carpet dust removal is a crucial step in the carpet washing process, playing a vital role in ensuring effective cleaning. Neglecting to remove dust from carpets can significantly compromise the overall cleaning quality.

When dust and particles are not properly separated before washing, they tend to leave residues in the gaps of the carpet fibers after the cleaning process.

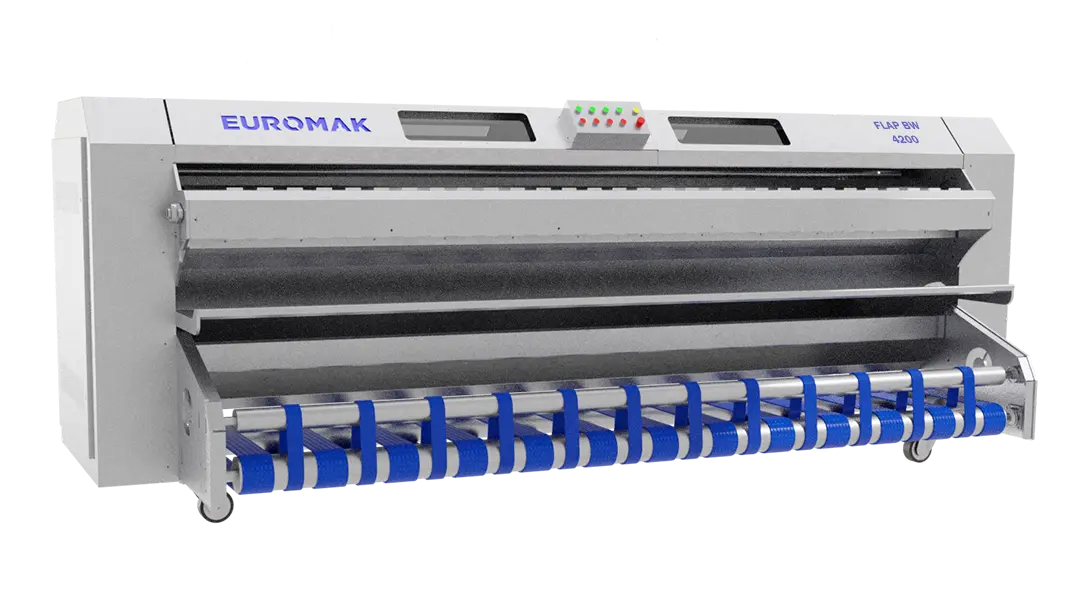

Carpet dust remover machines are instrumental in enhancing work efficiency by employing a powerful engine and a beating system. These machines apply high and equal impacts to every corner of the carpet, effectively dislodging and removing dust and particles.

By incorporating such technology, they contribute directly to achieving more efficient and thorough cleaning results.

What is the impact of industrial carpet dust remover machines on efficiency?

Whether you're running a newly opened carpet washing business or have an established one, building brand familiarity is essential. To achieve this, it is necessary to provide well-equipped services and strive for high customer satisfaction.

Efficient cleaning is the simplest way to ensure customer satisfaction. In this regard, the utilization of advanced carpet dust remover machines plays a pivotal role as they form the first and most crucial step in the carpet washing process.

Carpets that undergo the dust removal process experience a quicker washing stage and achieve superior cleanliness compared to carpets that are not treated. This not only increases work efficiency but also significantly reduces the

overall time required for business operations.