- 2 Komadni Valjak

- 4000 m³ Vakum

- 4500 m2 Dnevni Kapacitet

- 10+ Godina Performansi

- 2 Godina Garancije

Odkrijte Sami

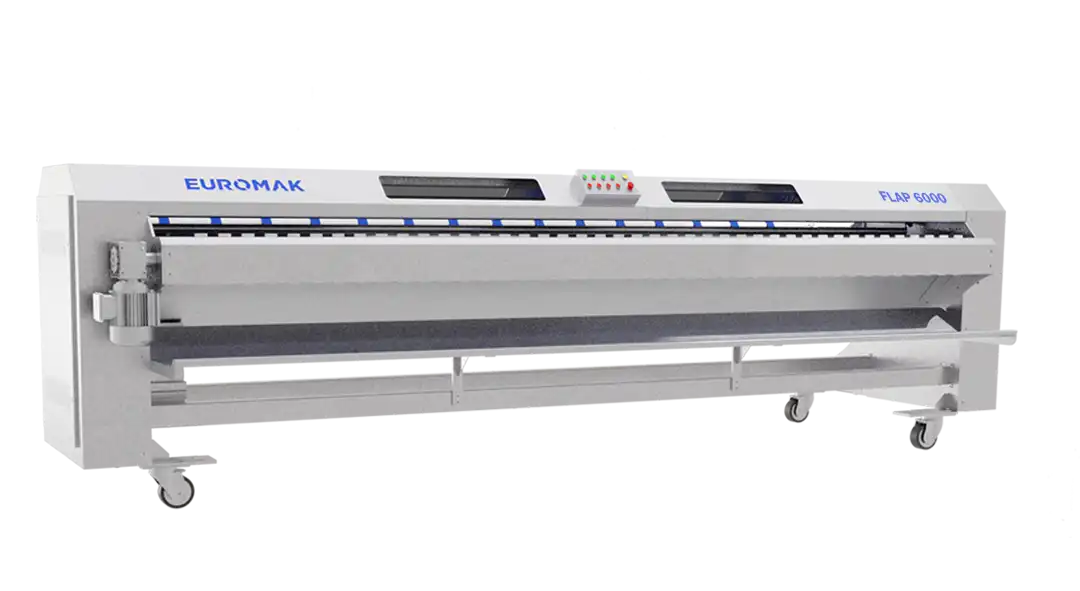

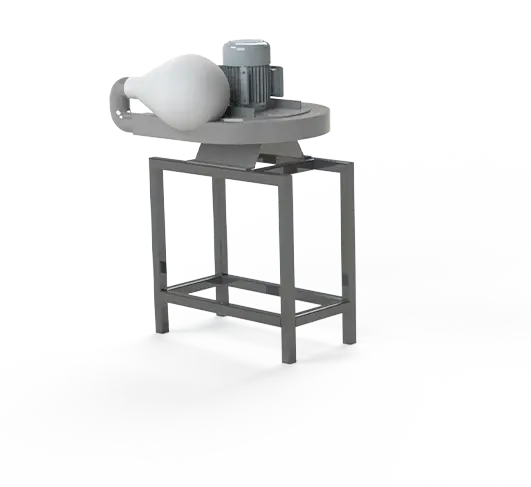

Napredni Sistem Za Klofanje

Dust Remover System

The carpet, which is placed in reverse to the belt system, is moved between the lower and upper beater rollers by the system. The beating roller system with 2 beating roller applies 2x208 blows to the carpet in one minute, beating every part of the carpet evenly. In this way, dust, pile, hair and foreign materials accumulated in the carpet are removed from the carpet.

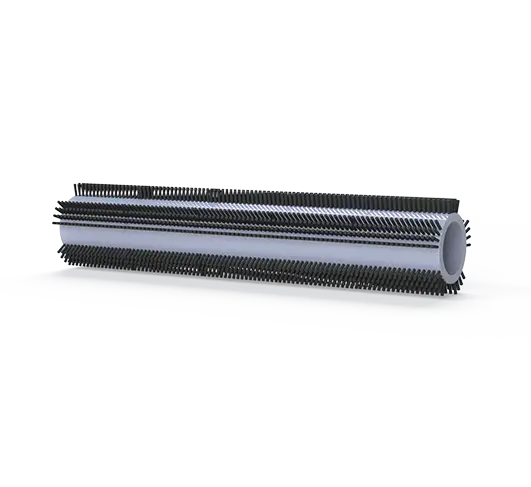

Sweeping Roller Brush

The carpet dust remover system helps to remove foreign particles that may be on the carpet. This process is realized by the roller brush with a diameter of 200 mm, which also undertakes the combing mission. As the carpet passes through the sweeping roller brush, the roller brush helps to remove substances such as adhesive from the carpet. The roller brush featured here has been specially developed and applied to the carpet combing process.

Carrier Brush System

Dust, hair and foreign objects collected in the machine chamber as a result of the dust removing and brushing process are carried out of the machine by the brushes placed on the belt. Through the conveyor belt system, the dust remover machine is allowed to operate more quietly and efficiently.

Dust Brush

It provides an effective dust removing process with its L:150 mm dust brush.

The Most Robust Body

Conveyor Belt

The conveyor belt system, which performs the carpet moving function, is safe and long-lasting. The two-way belt system allows the heavy carpets that need to be whipped to start again by first taking them back and then forwarding them through the back-and-forth control system.

Vacuum Process

It collects hair, the bristles, dust, dirt, etc. in the chamber by vacuuming after the dust removing and brushing process .Thanks to the powerful vacuum system, the spread of dust flying in the air is prevented.

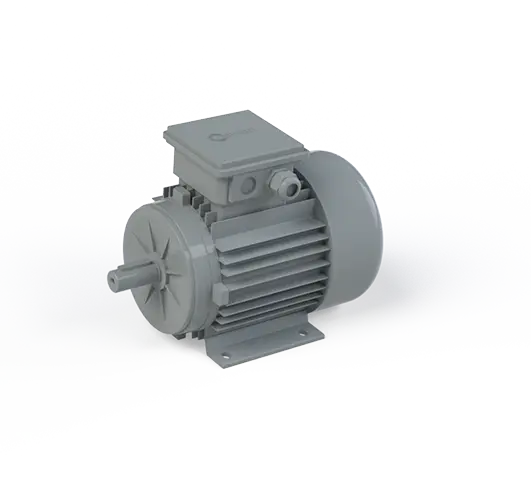

Engine

It provides high performance and efficiency with its 8.44 kW engine power. With a beating speed of 1-2 m/min, it is ensured the carpet to be purified from foreign materials.

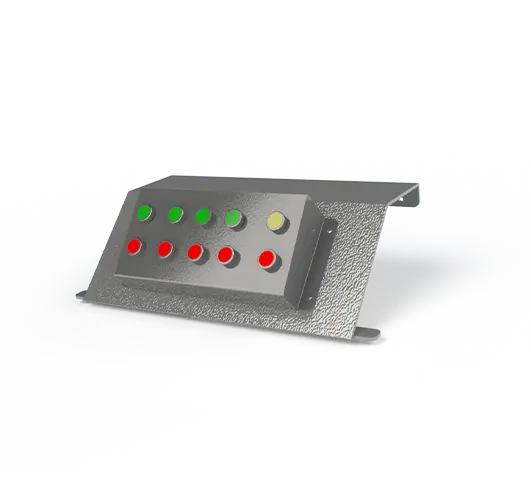

Future Generation Control

Movement System

Easy to use and accessibility with the help of the control panel on the machine provides a great advantage for the user. The electronic parts are used prefer to products that open to use for many years and will not cause malfunctions. Adjustable band speed is provided.

High Endurance

Material

Painted iron is used in the Flap 6000 for a long-lasting use.

Dimensions

The Flap 6000 has a length of 1850 mm, a width of 6820 mm and a height of 1450 mm.

Quality Management System

A quality management system is applied at every stage of the production phase and machines are produced and manufactured in CE standards. It is made ready for use without compromising the quality by performing the necessary tests and certification.

Global Standard Servis

Obrazovanje

Kao Euromak, pridajemo značaj postizanju maksimalne efikasnosti i kvaliteta svake mašine koju proizvodimo. Osiguravanje visokih performansi ostvaruje se odgovarajućom upotrebom mašinskih procesa. U ovom trenutku korisnicima se daju potrebne informacije i obuka o mašinama koje proizvodimo i osigurano je da se mašina maksimalno iskoristi.

Isporuka I Ugradnja

Mašine se utovaruju u dostavno vozilo sa materijalima za zaštitu od udara. Prilikom otpreme proizvodi se transportuju pažljivo i pažljivo kako ne bi došlo do oštećenja, a mašine koje se otpremaju se sklapaju sa korisnikom u skladu sa spremnošću za upotrebu.

Garancija

Mašine proizvedene od visoke izdržljivosti i kvalificiranih materijala dizajnirane su da budu prikladne za vašu upotrebu dugi niz godina. Za sve naše modele naša kompanija garantuje 2 godinu protiv grešaka u proizvodnji. Osim toga, naše mašine imaju garanciju od 5 godina u smislu rezervnih dijelova i napredne servisne podrške.

Podrška za održavanje širom svijeta

Mašine koje proizvodi Euromak izvoze se u više od 45 zemalja svijeta. Nudimo široku mrežu podrške i stručnih usluga širom svijeta protiv svih mogućih problema koji se mogu pojaviti.

Program životnog partnerstva

Kao Euromak, zadržali smo kontinuirani pristup uslugama već 15 godina sa proizvodnjom koje smo izvodili u procesu od dana osnivanja do danas. Uzimamo kao princip da budemo uz vas u svemu što vam je potrebno, od proizvodnje mašina do procesa nakon upotrebe.

A carpet cleaning machine is much more than a price tag on it. A machine that fails and waits for days, weeks for service/spare parts, no matter how cheap, will cost you dearly at the end of the day. In order for your investment to turn into profit, the manufacturer must have a mission to add value to your business. As Euromak, we are proud and happy to be that company.

Bünyamin Demircan, CEO