- 2300 mm. Inner Drum Length

- 1200 rpm Spin Cycle

- 1000 m2 Daily Capacity

- 10+ Years High Performance

- Cover Manual / Pneumatic

- 2 Year Warranty

Explore By Yourself

Technological Control System

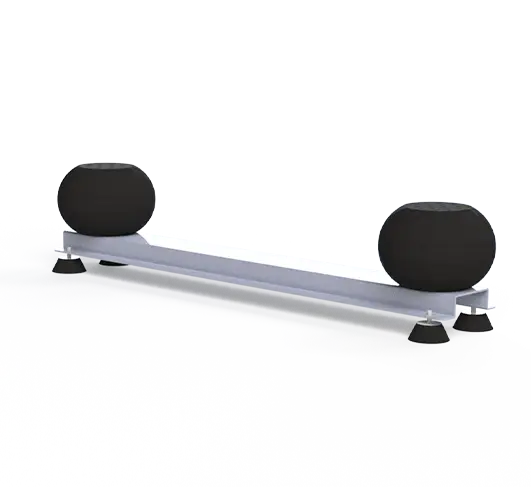

Suspension System

The entire system is designed primarily unbalanced during the manufacturing process. Various vibrations can occur with the carpets will be spinned due to type, thickness, length, width and etc many factors. In addition, there is a vibration situation during the start and stop of the machines. In order to prevent this and to provide a longer lasting experience, the airbag (shock absorber) system has been added. This suspension system is one of the most important parts that affect the use of spinning machines.

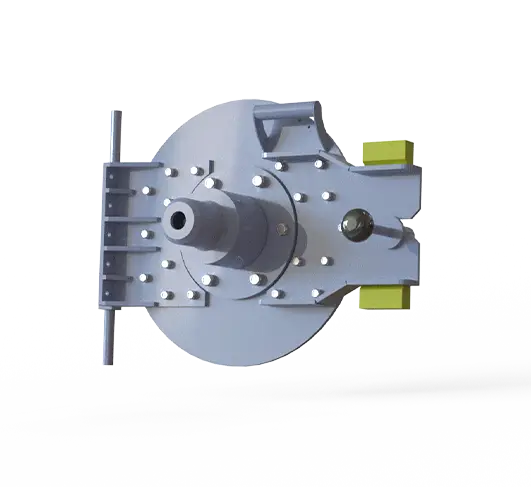

Cover System

Pneumatic or manual cover system is optionally available on Spin 2300. The closing process of the cover takes place with the effect of air pressure and vacuum. The cover system, which is the most sensitive part of the spinning machines, provides performance experience without problem by increasing the lifetime of the machine if it is designed correctly. As a result of the R&D and innovation studies carried out with a professional team in the field, the cover problem that may occur in the spinning machines has been minimized.

Movement System

Easy use and accessibility with the help of the control panel on the machine provides a great advantage for the user. Thanks to the time relay it has, the spinning process is completed automatically. In the electronic parts used, products that are open for use for many years and that will not cause malfunctions are carefully preferred.

Speed Control

With the speed control system integrated into the panel, many parts of the machine are prevented from being worn quickly and easily by the principle of working from slow to fast and from fast to slow during the start and stop stages. This system extends the service life of the spinning machines.

Performance-Oriented Innovation

Engine

It provides high performance and efficiency with its 4 kW motor power.

Spin-Cycle

In the carpets placed in the spinning machine based on the rotation direction, the most appropriate speed operation and the centrifugal method are applied to ensure discharge the water . Spin cycle of Spin 2300 is 1200rpm. 10% wetness remains in each carpet spinned at the appropriate cycle.The most important issue to be considered here is to determine the rotation speed that will both spinning well and not wear out the machine. This is an important consideration for working parts.

Pragmatist Production Approach

Material Selection

Carpet spinning machines are designed by our engineers purposefully, considering used materials all details like specifications,thikness and ideal weight .Considering cases such as working hour,rotation cycles and lubrication system in the choosing of material for the bearings and beds, selections are made with care and attention.

Drum

In Spin 2300, the inner drum diameter is 380 mm and the inner drum length is 2300 mm. Stainless steel is used as the inner drum material, suitable for long-term use.

Dimension

The Spin 2300 has a length of 2955 mm, a width of 1100 mm and a height of 1500 mm.

Quality Management System

A quality management system is applied at every stage of the production phase and machines are produced and manufactured in CE standards. It is made ready for use without compromising the quality by performing the necessary tests and certification.

World Class Services

Training

As Euromak, we care about getting maximum efficiency and quality from every machine we produce. Providing high performance is achieved with a use in accordance with machine processes. At this point, necessary information and trainings are given to the users for the machines we manufacture, and it is ensured that the machine is utilized at the highest capacity.

Shipping and Installation

The machines are loaded onto the shipping vehicle with protective materials against impacts. During the shipment, the products are carefully transported without any damage, and the shipped machines meet to the user in accordance with ready to use.

Warranty

Machines produced with high durability and quality materials are designed to be suitable for your long use. All models are guaranteed 2 years against the manufacturing defects .In addition, our machine, spare parts availability and advanced service equipment are guaranteed for 5 years.

Worldwide Maintenance Support

The machines produced by Euromak are exported to more than 45 countries around the world. We offer a worldwide support and expert service network against all possible problems.

Lifelong Partnership Program

As Euromak, we have been following an understanding of uninterrupted service for 15 years with the productions we have realized in the process since the day we were founded. We make it our principle to be with you in every matter you need, from machine production to the process after use.

A carpet cleaning machine is much more than a price tag on it. A machine that fails and waits for days, weeks for service/spare parts, no matter how cheap, will cost you dearly at the end of the day. In order for your investment to turn into profit, the manufacturer must have a mission to add value to your business. As Euromak, we are proud and happy to be that company.

Bünyamin Demircan, CEO